FADGI Process

Why choose an iterative approach to implementing FADGI?

We had an already established high quality production workflow, including quality assurance checks, with existing demands for output. By iterating our approach to adopting tools in measuring FADGI compliance, we were able to learn over time while still providing service to our collaborators in the library. There are also several material formats that are not as measurable through FADGI tools, such as transmissive materials (like photographic negatives and slides), mixed lighting (gold leaf and watermark digitization) and objects that are three-dimensional (like games). Even when not possible to meet FADGI compliant standards, we strive to follow many of the principles outlined in the FADGI document, such as meeting resolution levels even if other metrics cannot be met. We needed practical steps in adapting our workflows to new equipment, workflows and adopting FADGI.

Our Process

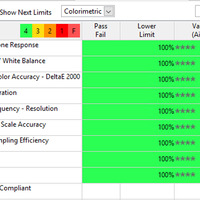

People often ask “what is that color bar thing”? It helps us calibrate our images and ensure our image quality! We include them in every batch of files we create, and sometimes with every file (an item level target). We can visually note if the color is presenting normally on our color calibrated monitors, check focus and exposure values, but there are other more precise tools we have now too that can run the files we create through algorithms that present data on the less humanly observable traits of our images (if anyone remembers the conversation about the dress that appeared blue and black to some and gold and white to others, you’ll know why it’s so important and helpful to have numbers and impartial opinions when it comes to color evaluation!) ROIs (regions of interest, also return on investment – all the time we spend digitizing it’s great to know we’re doing it accurately) are the little green boxes, as seen in the screenshot below, of an item level target about to have its FADGI measurements computed.

Digitizing and technology are ever evolving. Jumping into FADGI testing, this is what we’ve done so far:

- We worked with vendor support to explore Open-Source solutions. We used OpenDICE workflows to test our item level targets for quality and accuracy.

- We installed everything and internally documented those steps.

- We worked with vendor support to explore proprietary software solutions for workflow efficiencies.

- We shared our skills internally with our team, and iterated on our setups to improve our quality measurements.

- We connected with other institutions who were either embarking on similar work, had already succeeded, or were trying to explore FADGI verification processes in their workflows and shared notes.

- We learned via virtual training opportunities February through April 2023 instructed by Jim Studnecki and Don Williams to help skill up as professional development.

- We practiced with our setups and iterated on our best work, sustainably improving our output.

- We documented our results and created internal references for both test iterations. These include a spreadsheet to remind us what we've tried, (and worked and what hasn't) and the processes we developed (including a glossary of terminology hyperlinked to available online resources).